Company News

NEW CNC plasma metal cutting service using our new in-house Swift Cut XP machine

What is plasma cutting?

Plasma cutting is a process that precisely cuts metal sheets and plates using an electrical current and compressed inert gases which are passed through a fine nozzle at high speeds. The high-velocity jet of ionized gas (plasma) melts and blows away the metal, creating a clean and accurate cut.

What is ‘CNC’?

CNC is an acronym for ‘Computer Numerical Control’. In the context of our new CNC plasma cutting machine much of the cutting process is automated. The whole process involves CAD (Computer Aided Design, we use Autodesk, Advance Steel), to draw out the cutting pattern. This is followed by CAM (Computer Aided Manufacture), SwiftCAM is the application that converts the CAD drawing into ‘G-Code’ which instructs the cutting torch to follow a logical path when operating. Then Swift CNC is the software that controls the machine.

Our machine consists of a table where the metal is placed, a computer-controlled gantry system that moves the plasma torch along the desired cutting path, and a power supply that generates the plasma arc. The CNC system allows for precise control of the torch movement, enabling complex and intricate shapes to be cut with ease.

What is the CNC plasma machine used for?

CNC plasma cutting machines are commonly used in industries such as manufacturing, fabrication, automotive, and construction, where accurate and efficient metal cutting is required. They offer advantages such as high cutting speeds, versatility in cutting various thicknesses of metal, and the ability to work with different types of metals, including steel, aluminium, and stainless steel.

The primary purpose for us at Westcountry Fabrication Ltd investing in this plasma machine was to bring in house the cutting of plates for structural steel work. The machine can be programmed to cut plates accurately and efficiently, a process which previously we were doing manually for small jobs or sub-contracting out to other cutting firms on larger jobs. Both were taking up significant amounts of time, and we are noticing increasing lead times from our sub-contractor. Now we have the machine in house we have greater opportunities to meet tight deadlines and meet customer demand by shortening our fabrication lead times.

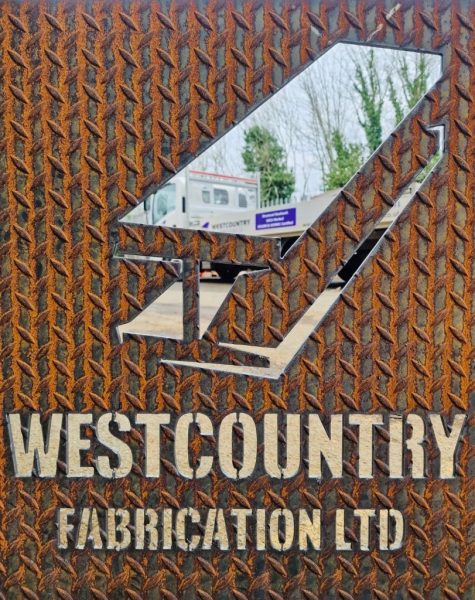

Due to the versatility and efficiency of the machine we are now able to offer additional services, including bespoke cut metal signage in a range of material, including Corten, Stainless and Mild Steel. These signs can include business names, company logos or house names. These signs are an effective, high-end and durable addition to any home or business and can be made to cater for your unique style whether you prefer the rustic Corten or the modern and clean aesthetic of stainless steel.

Which machine do we have?

We chose to invest in the Swift-Cut XP, for more information on this see here. After visiting the showroom our director Jack was impressed with the ease of operation and heavy-duty capability of this machine. Details from Swift-Cut:

The Swift-Cut XP is ideal for the heavy duty and high production environment. Highly reliable, faster, and stronger, this machine has been designed to maximise uptime. It can handle a sheet of metal up to 32mm in thickness.

- Heavy duty cutting

- Six plasma power source options (12mm – 30mm pierce capacity)

- Mixed gas cutting available using Max Pro 200 power source*

- Improved edge finish*

- Less dross, less taper and faster cut speeds*

- Longer consumable life*

- Designed with production cutting in mind (all day everyday)

- Helical Rack on X & Y axis for maximum repeatability

- Heavy duty gantry end castings with machined faces

- AC servos motors deliver exceptional positioning accuracy

- Twin x-axis linear rails for rigidity

- 200mm gantry height clearance for box section cutting etc.

- Works in conjunction with the Hypertherm MAXPRO200’

Plasma cut metal sign for The Crewing Company- ‘For freelance production and post-production talent’

Contact us:

We are an established fabrication firm with a factory based in Saltash, just over the Tamar from Plymouth. Following our investment in new machinery we can now provide a new efficient and competitively priced plasma metal cutting service to businesses across Devon and Cornwall. Contact us for a quote sales@westcountryfabricationltd.co.uk. We offer a quick turnaround on production of precisely cut plates, panels or signs from a range of metal and are happy to discuss bespoke plasma cut metal requirements.